Why Ribs are Important in TMT Bars?

What is Rib in TMT Bars?

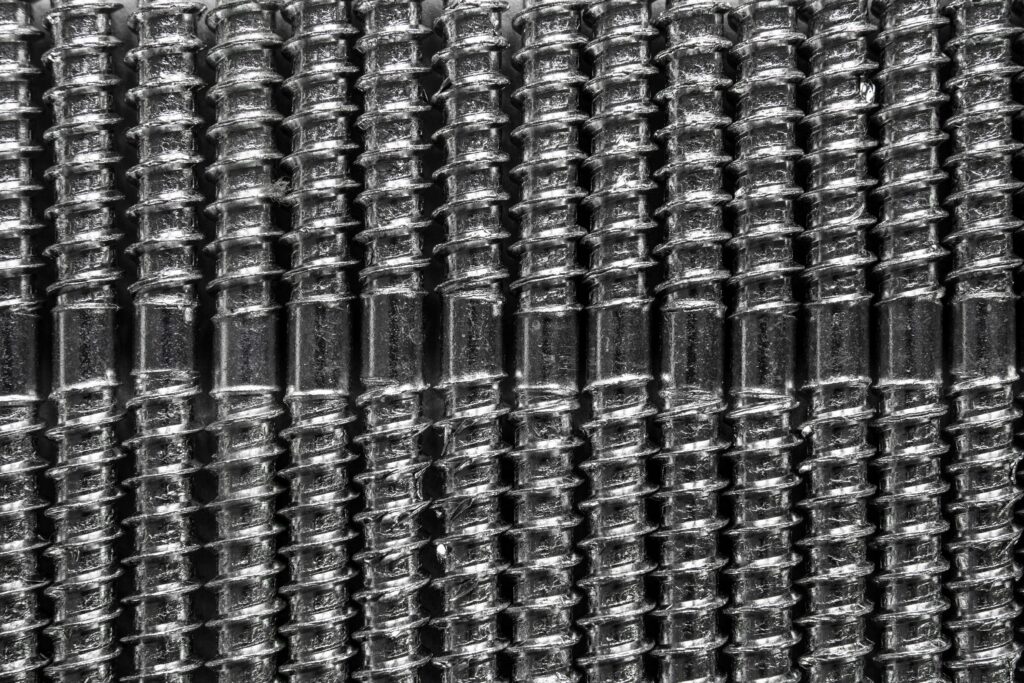

In the construction industry, Thermo-Mechanically Treated (TMT) bars are essential for building reinforced concrete structures. A distinctive feature of these bars is the raised patterns, or “ribs,” running along their surface. These ribs are not merely decorative; they play a vital role in enhancing the performance of the bars. The ribs are continuous, raised deformations designed to improve the bond between the steel and the surrounding concrete, ensuring that the two materials work together effectively to resist loads and maintain structural integrity.

How Many Types of Rib?

Ribs on TMT bars are categorized into two main types:

- Transverse Ribs: These ribs run perpendicular to the length of the bar, forming ring-like patterns around its surface. They act as anchors within the concrete, preventing the bar from slipping and enhancing its ability to resist shear forces. This feature is crucial for the stability of structures, especially in areas prone to seismic activity.

- Longitudinal Ribs: Running parallel to the length of the bar, longitudinal ribs create continuous lines along its surface. These ribs enhance the anchorage of the bar within the concrete, providing greater resistance to being pulled out under tensile stress. This characteristic is particularly important in beams and columns, which are subjected to significant tensile forces.

Why Rib is Used in TMT Bars?

The primary purpose of incorporating ribs into TMT bars is to enhance the mechanical interlock between the steel and the concrete. This interlocking mechanism is vital for the structural performance of reinforced concrete, as it increases the surface area of contact between the materials, thereby improving bond strength. This enhanced bond is essential for the load-sharing mechanism between the steel and concrete, ensuring that they function as a cohesive unit to bear and distribute loads efficiently.

Why Rib is Important in TMT Bars?

Ribs in TMT bars are crucial for several reasons:

- Enhanced Bond Strength: The ribs create a rough surface on the TMT bars, increasing frictional force and ensuring a stronger bond between the steel and the concrete. This bond is critical for preventing the bars from slipping or being pulled out, which can compromise the structural integrity of the building.

- Improved Load Transfer: The ribbed design ensures efficient load transfer from the concrete to the steel, minimizing stress concentrations and potential failure points. This feature contributes significantly to the overall stability and safety of the structure.

- Resistance to Cracking and Slippage: The interlocking action provided by the ribs reduces the likelihood of cracking and slippage, even under extreme conditions such as heavy loads or seismic events. This is particularly important for the longevity and durability of the structure.

- Increased Structural Integrity: By enhancing bond strength, load transfer, and resistance to cracking, ribs significantly improve the structural integrity of buildings. This leads to more durable and long-lasting structures capable of withstanding various environmental and mechanical stresses.

Importance of Rib in TMT Bars

The importance of ribs in TMT bars extends beyond basic structural integrity:

- Seismic Performance: In earthquake-prone areas, ribbed TMT bars are essential for absorbing and dissipating seismic energy, helping prevent catastrophic failures like collapses.

- Durability and Longevity: Ribs help protect TMT bars from environmental factors such as corrosion. The improved bond with the concrete reduces moisture ingress, which can lead to corrosion and deterioration of the steel.

- Economic Efficiency: The enhanced bond strength provided by ribbed TMT bars allows for better utilization of the steel’s properties, potentially reducing the amount of steel required for a project. This can lead to cost savings without compromising safety or durability.

Benefits of Rib in TMT Bars

Ribs in TMT bars offer numerous benefits:

- Enhanced Safety: The stronger bond between the steel and concrete enhances the safety of the structure, especially in critical infrastructure such as bridges and high-rise buildings.

- Improved Structural Performance: Ribs enable TMT bars to better resist forces such as tension, compression, and shear, improving the overall structural performance and resilience.

- Long-Term Durability: Enhanced bond strength and resistance to environmental factors contribute to the long-term durability of the structure, reducing the need for maintenance and repairs.

Best Quality of TMT Bars

When it comes to choosing the best TMT bars for your construction projects, quality is paramount. RHL Profiles, a leading TMT bar manufacturer in Kanpur, Uttar Pradesh, is dedicated to providing high-quality TMT bars that meet the highest industry standards. Our bars are produced using advanced technology and undergo rigorous quality control processes, ensuring their superior performance and durability.

At RHL Profiles, we understand the importance of using the best quality TMT bars in construction. Our TMT bars are designed to provide superior strength, excellent bond strength, and enhanced durability. Whether you are constructing residential buildings, commercial complexes, or infrastructure projects, our high-quality TMT bars in Kanpur and across Uttar Pradesh are the ideal choice for ensuring the safety and longevity of your structures.

For those looking for the best TMT bars in Kanpur, RHL Profiles stands out as a trusted name. Our reputation as the best TMT bars manufacturer in Kanpur is built on our commitment to quality and customer satisfaction. We are also recognized as the best TMT bars manufacturer in Uttar Pradesh, providing materials that meet the highest industry standards.

In the regions of Lucknow, Prayagraj, and beyond, RHL Profiles is known for supplying the best TMT bars. Our products are designed to meet the diverse needs of various construction projects, ensuring that every structure built with our TMT bars is safe, durable, and compliant with industry standards.

Choosing the best TMT bars in Uttar Pradesh means selecting a product that provides both strength and longevity. RHL Profiles ensures that our TMT bars offer the best performance characteristics, making them the preferred choice for builders and contractors. Whether you’re looking for the best TMT bars in Kanpur or across the state, our bars are crafted to meet the rigorous demands of modern construction.

The best quality TMT bars from RHL Profiles are known for their superior tensile strength, which is critical for resisting the various forces that structures are subjected to. Our bars are designed to provide maximum safety and durability, making them the ideal choice for all types of construction projects.

For builders and contractors seeking the best TMT bars in Lucknow, RHL Profiles offers products that combine quality, performance, and affordability. Our TMT bars are manufactured using the latest technology, ensuring they meet the highest standards of quality and safety. This makes them the top choice for those who value reliability and excellence in their construction materials.

In addition to our presence in Kanpur, RHL Profiles is also a leading provider of high-quality TMT bars in Uttar Pradesh. Our commitment to delivering the best TMT bars in Kanpur and beyond ensures that your projects benefit from materials that offer superior performance and reliability.

Conclusion

In conclusion, the ribs in TMT bars are essential for the performance and durability of reinforced concrete structures. They enhance the bond between steel and concrete, improve load transfer, and provide resistance to cracking and slippage. These features are crucial for maintaining the structural integrity and safety of buildings.

For the best TMT bars in Kanpur or the best TMT bars in Uttar Pradesh, RHL Profiles is your go-to source. Our commitment to quality and excellence ensures that you receive the best materials for your construction projects. Contact us today to learn more about our high-quality TMT bars and how they can benefit your next project.

Contact Information:

- Email: contact@rhlprofiles.com

- Phone: +919839146442

- Office Address: 63/2, City Centre, The Mall, Kanpur (208 001) Uttar Pradesh, India

Build with confidence and quality with RHL Profiles, your trusted partner in construction.

RHL Updates

Latest Updates

- January 2026

- December 2025

- November 2025

- October 2025

- September 2025

- August 2025

- July 2025

- June 2025

- May 2025

- April 2025

- March 2025

- February 2025

- January 2025

- December 2024

- November 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- December 2023

- October 2023

- September 2023

- August 2023

- July 2023

- May 2023

- April 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- September 2022

- July 2019

- June 2019

- Best Quality TMT Bars

- Best Saria in Prayagraj

- Best Sariya in Lucknow

- Best TMT Bar in Prayagraj

- Best TMT Bar Manufacturer in Unnao

- Best TMT Bars in Agra

- Best TMT Bars in Allahabad

- Best TMT Bars in Ambedkar Nagar

- Best TMT Bars in Ayodhya

- Best TMT Bars in Azamgarh

- Best TMT Bars in Ballia

- Best TMT Bars in Banaras

- Best TMT Bars in Chandauli

- Best TMT Bars in Chitrakoot

- Best TMT Bars in Deoria

- Best TMT Bars in Gautam Buddh Nagar

- Best TMT Bars in Gorakhpur

- Best TMT Bars in Jaunpur

- Best TMT Bars in Jhansi

- Best TMT Bars in Kanpur

- Best TMT Bars in Kushinagar

- Best TMT Bars in Lakhimpur Kheri

- Best TMT Bars in Lalitpur

- Best TMT Bars in Lucknow

- Best TMT Bars in Meerut

- Best TMT Bars in Noida

- Best TMT Bars in Pratapgarh

- Best TMT Bars in Raebareli

- Best TMT Bars in Sant Kabir Nagar

- Best TMT Bars in Unnao

- Best TMT Bars in Uttar Pradesh

- Best TMT Bars in Varanasi

- Best TMT Bars Manufacturer in Uttar Pradesh

- Featured

- Quality TMT Bars Manufacturer in UP

- Saria Distributor in Kanpur

- TMT Bar Manufacturer in Uttar Pradesh

- TMT Bars in Basti

- Today TMT Bars updates

- Uncategorized

Categories

उत्तर प्रदेश का सबसे भरोसेमंद सरिया

- Best Quality TMT Bars

- Best Saria in Prayagraj

- Best Sariya in Lucknow

- Best TMT Bar in Prayagraj

- Best TMT Bar Manufacturer in Unnao

- Best TMT Bars in Agra

- Best TMT Bars in Allahabad

- Best TMT Bars in Ambedkar Nagar

- Best TMT Bars in Ayodhya

- Best TMT Bars in Azamgarh

- Best TMT Bars in Ballia

- Best TMT Bars in Banaras

- Best TMT Bars in Chandauli

- Best TMT Bars in Chitrakoot

- Best TMT Bars in Deoria

- Best TMT Bars in Gautam Buddh Nagar

- Best TMT Bars in Gorakhpur

- Best TMT Bars in Jaunpur

- Best TMT Bars in Jhansi

- Best TMT Bars in Kanpur

- Best TMT Bars in Kushinagar

- Best TMT Bars in Lakhimpur Kheri

- Best TMT Bars in Lalitpur

- Best TMT Bars in Lucknow

- Best TMT Bars in Meerut

- Best TMT Bars in Noida

- Best TMT Bars in Pratapgarh

- Best TMT Bars in Raebareli

- Best TMT Bars in Sant Kabir Nagar

- Best TMT Bars in Unnao

- Best TMT Bars in Uttar Pradesh

- Best TMT Bars in Varanasi

- Best TMT Bars Manufacturer in Uttar Pradesh

- Featured

- Quality TMT Bars Manufacturer in UP

- Saria Distributor in Kanpur

- TMT Bar Manufacturer in Uttar Pradesh

- TMT Bars in Basti

- Today TMT Bars updates

- Uncategorized