What is high ductile tmt bars

High Ductile TMT Bars: Understanding Ductility in Steel Bars

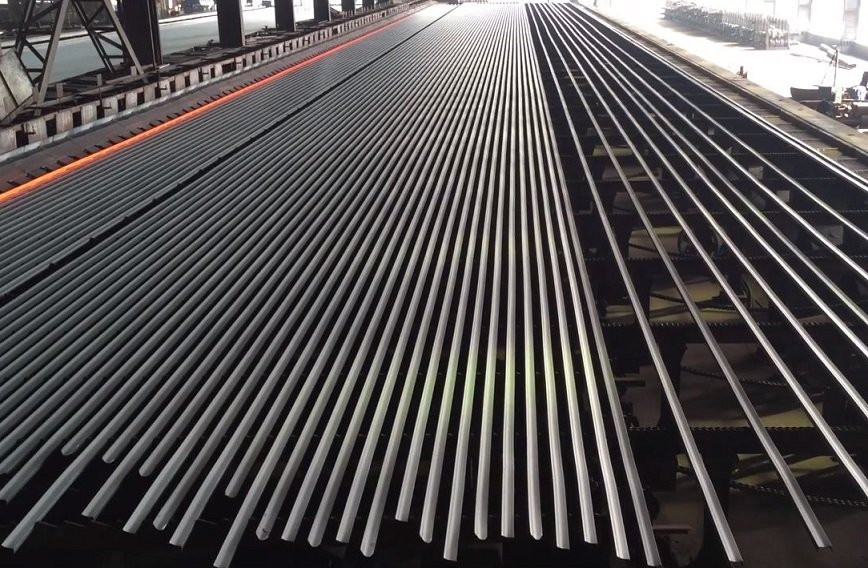

TMT bars, also known as Thermo-Mechanically Treated bars, are widely used in construction projects as reinforcement bars. They are known for their high strength, durability, and corrosion resistance. However, another important factor to consider when choosing TMT bars is their ductility. In this blog, we will discuss what ductility is in TMT bars, what high ductile steel is, and what the most ductile steel bar is.

What is Ductility in TMT Bars?

Ductility is the ability of a material to deform under tensile stress without breaking. In the case of TMT bars, ductility is an important factor to consider because it ensures that the bars can withstand the stress and strain that they are subjected to during construction. TMT bars with high ductility are more flexible and can be bent without breaking.

What is High Ductile Steel?

High ductile steel is steel that has high ductility. It is also known as earthquake-resistant steel because it can withstand the stress and strain that occur during earthquakes. High ductile steel is made by adding certain elements, such as vanadium, to the steel. These elements help to improve the steel’s ductility and strength.

What is the Most Ductile Steel Bar?

The most ductile steel bar is the Fe-415 TMT bar. Fe-415 TMT bars are made by adding elements like vanadium, chromium, and copper to the steel. These elements help to improve the ductility, strength, and corrosion resistance of the bars. Fe-415 TMT bars are widely used in construction projects because of their high ductility and strength.

Advantages of High Ductile TMT Bars

High ductile TMT bars offer several advantages over traditional TMT bars, including:

- Increased Flexibility – High ductile TMT bars are more flexible than traditional TMT bars. This makes them easier to work with and allows for greater design flexibility.

- Improved Safety – High ductile TMT bars are more resistant to earthquakes and other natural disasters. This makes them safer to use in construction projects.

- Better Corrosion Resistance – High ductile TMT bars are more resistant to corrosion than traditional TMT bars. This means they last longer and require less maintenance.

- Increased Strength – High ductile TMT bars are stronger than traditional TMT bars. This means they can withstand greater stress and strain during construction.

Conclusion

Ductility is an important factor to consider when choosing TMT bars for construction projects. High ductile TMT bars offer several advantages over traditional TMT bars, including increased flexibility, improved safety, better corrosion resistance, and increased strength. The Fe-415 TMT bar is the most ductile steel bar and is widely used in construction projects because of its high ductility and strength.