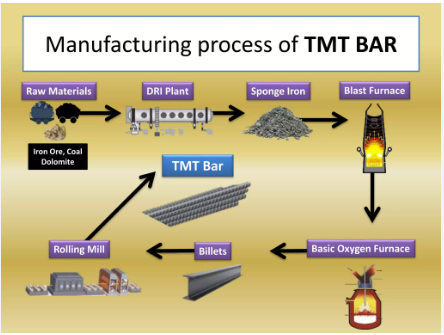

Raw Material: The process begins with the procurement of high-grade iron ore, coal, and dolomite. These raw materials are crushed and ground to a fine powder and then mixed in the right proportion to produce the required quality of steel.

Melting: The raw materials are then melted in a furnace to produce a liquid steel. The furnace used for this process is typically an electric arc furnace or a induction furnace.

Temperature Control: The temperature of the liquid steel is carefully controlled during the TMT process. It is heated to the required temperature and then cooled at a specific rate to achieve the desired properties in the steel.

Rolling: The liquid steel is then poured into a rolling mill where it is rolled into bars of the required size and shape.

Quenching: The hot bars are then cooled rapidly by quenching in water or oil. This process is known as quenching and it changes the microstructure of the steel, making it harder and stronger.

Tempering: The bars are then tempered to relieve internal stresses and improve ductility.

Inspection: The TMT bars are then inspected for quality and compliance with the Indian Standards (IS: 1786-2008)

Packaging and Dispatch: After passing the inspection, TMT bars are packaged and dispatched to the customers.

TMT Steel Bar Grades & Applications Explained

The most common TMT steel bar grades are:

(2). Fe 500: This grade of TMT steel bars has a minimum yield strength of 500 N/mm². It is suitable for use in medium-rise buildings and other structures that experience moderate levels of stress.

(3). Fe 550: This grade of TMT steel bars has a minimum yield strength of 550 N/mm². It is suitable for use in high-rise buildings and other structures that experience high levels of stress.

(4).Fe 600: This is the highest grade of TMT steel bars, with a minimum yield strength of 600 N/mm². It is used in special structures such as dams, bridges, and other structures that experience very high levels of stress.